Services for you

The latest generation production management system

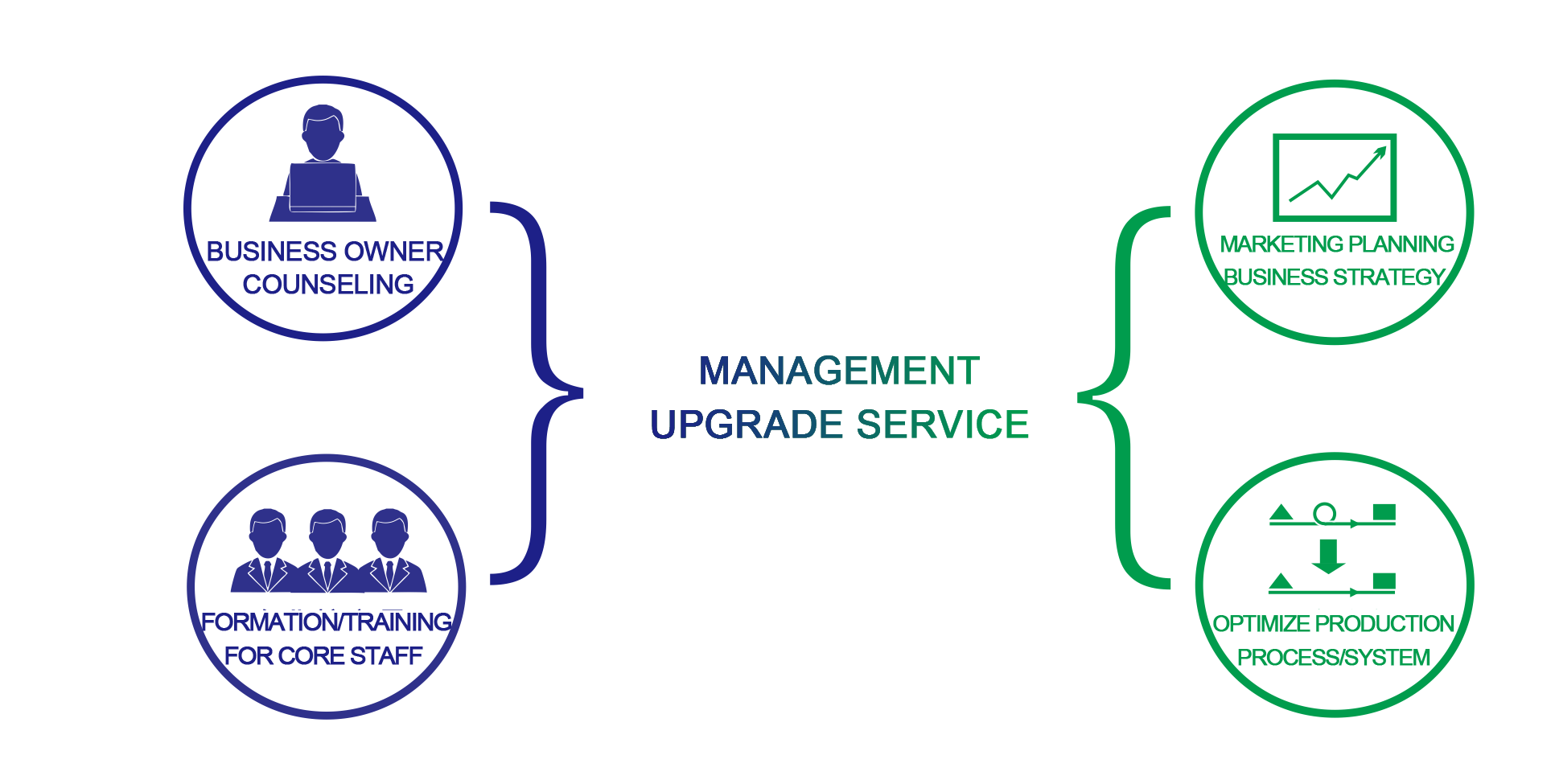

Management Upgrade Service

Aiming at the conflicts between the current informationization trend and the traditional enterprise management methods, as well as the management difficulties caused by the scale expansion and industry characteristics, the solution are obtained. We assist enterprises to optimize internal organizational structure, solve management system loopholes, and improve business strategies.

Organizing

Starting from the two sides of the enterprise boss and its core team, through the analysis of the organizational structure of the enterprise,the power-responsibility-profit chain of the enterprise is made clear. Clarify the responsibilities and power boundaries of personnel at all levels, improve the management of the enterprise, and reduce the internal friction caused by the organizational structure.

Management consulting

Fully understand the industry in which the customer is located, and go deep into the company to conduct on-site investigations. Combining the advanced modes and laws of management, we propose improvement suggestions for the inefficient and redundant parts of the current management of the enterprise, so that the operating mechanism of the enterprise can be improved, the productivity is maximized, and the economic benefits are improved.

Business planning

According to the current market situation and future development trends, combined with the changes in internal and external environmental conditions, we will give decision-making advice on long-term development planning. Help enterprises to rationally use human, material and financial resources to organize and plan business operations. Reduce business risks to a certain extent and seize market opportunities.

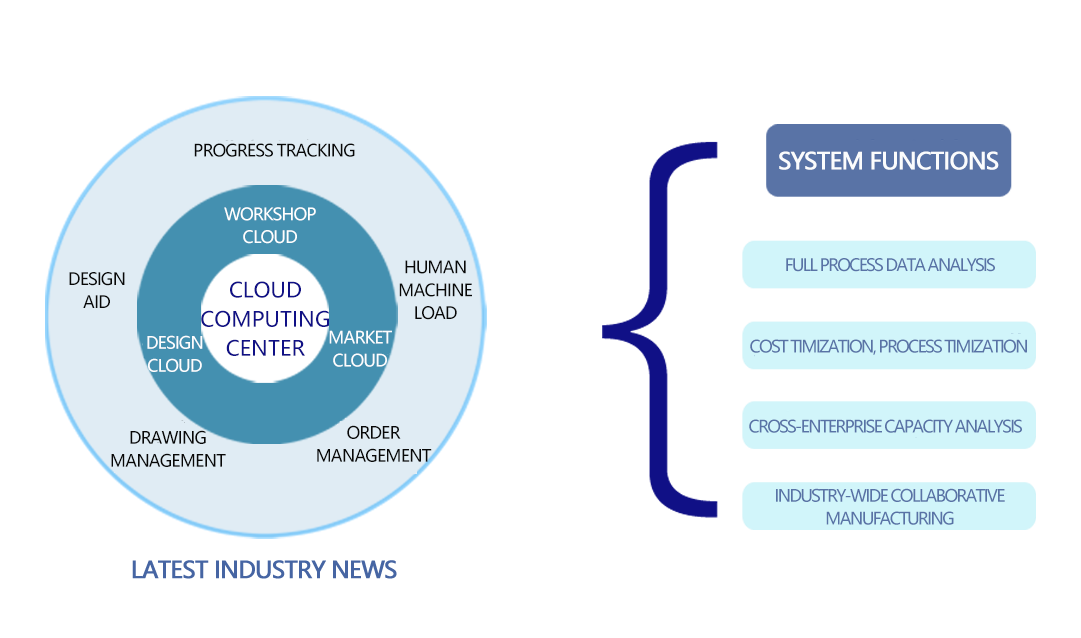

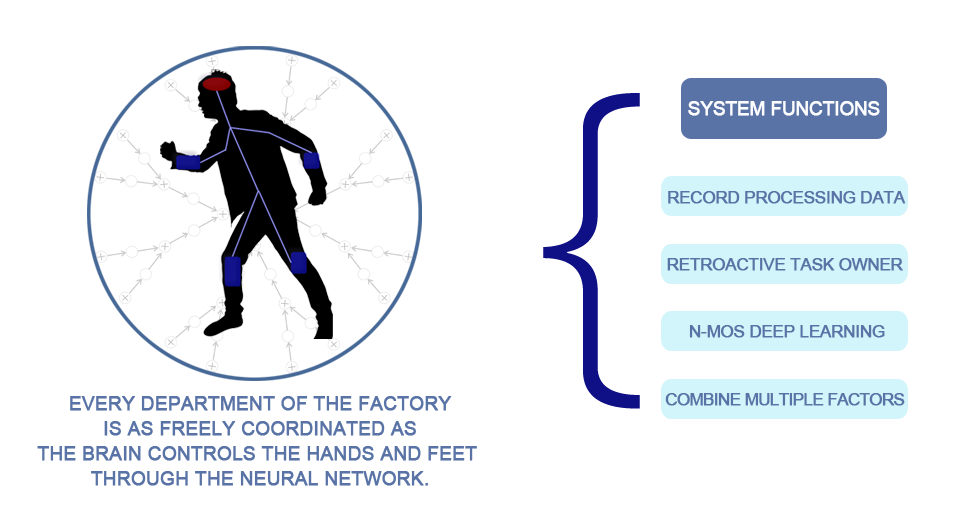

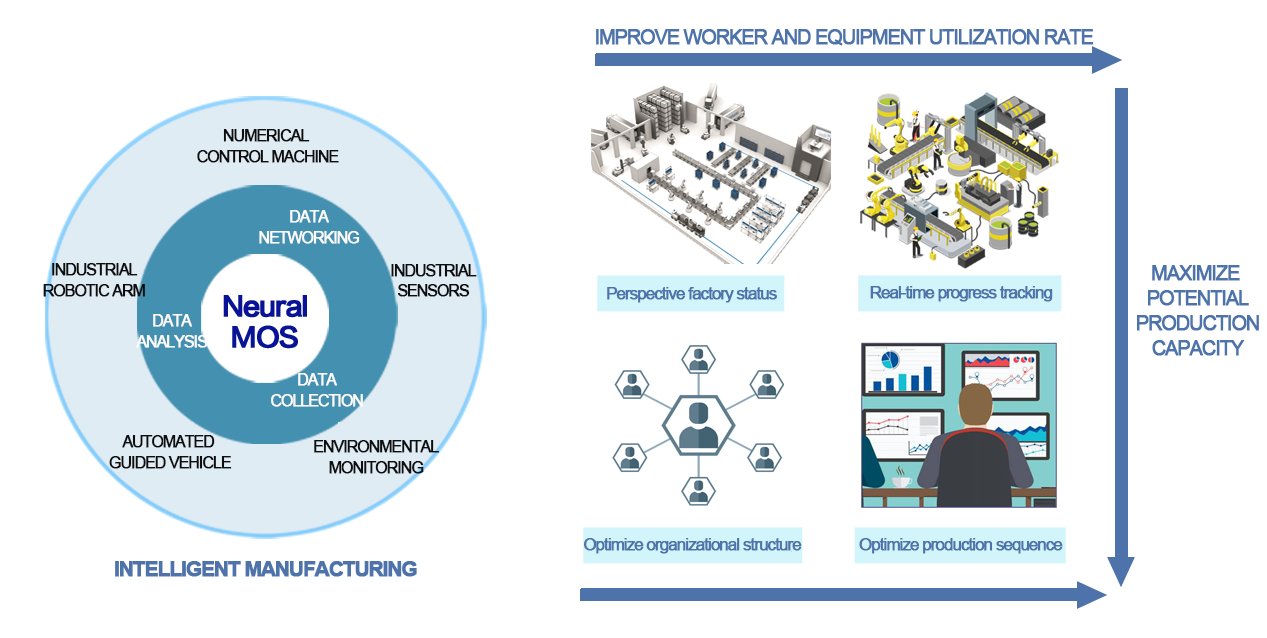

Neural-MOS

The Neural-Manufacturing Operating System is a new generation production management system that Bincube refines for the information needs of production enterprises. The system uses digital information technology and cloud computing technology as a means to digitally transform the machine shop to increase production capacity, reduce costs and shorten delivery.

Principles and characteristics of N-MOS system

The system is based on the human-based unit and the enterprise's power-responsibility setup, which is in line with the actual management of the enterprise. It can effectively avoid information islands, improve collaboration efficiency, and maximize organizational vitality.

N-MOS Focus

The system focuses on solving the production problems of flexible manufacturing companies with low efficiency and insufficient capacity. The system integrates customer orders, organizational structure, functional departments, equipment status, data collection, and remote operation within the enterprise to maximize potential production capacity.

N-MOS composition

N-MOS server

N-The N-MOS server integrates data storage and computing. Based on the core algorithm of the neural network, it collects and processes the feedback information of each terminal in real time, and provides support for the functions of intelligent scheduling, file sharing and cost analysis of the manufacturing operating system.

Tablet & Mobile App

Provides dedicated Apps for smart tablets and mobile phones, with cost query, mold management and instant messaging, allowing real-time viewing of work hours and changing production priorities at any time, providing more convenient terminal operations for information applications.

Computer application software

Maximize the use of existing office workers' computers and install N-MOS application software on the computer. Managers can arrange production tasks, view production schedules, share production materials, and communicate production conditions.

Wireless AP+AC system

Bincube Industrial Grade Wireless AP+AC System has a unique dual-link backup function to ensure stable connection. The system can also set different priorities for different types of information to ensure unimpeded data transfer between the central server and the terminal.

Function module introduction